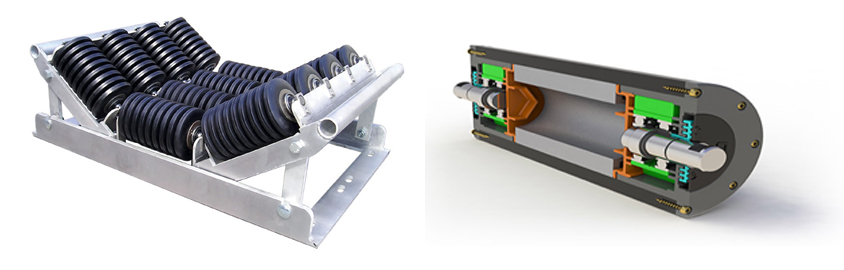

Belt Conveyor Idlers

We are one of the leading suppliers of various types of bulk and package handling conveyors and their components like Idlers, Rollers, Pulleys and Frames etc.

We have designed and supplied idlers in different Toughing Angles and for various usages for a wide range of Belt Conveyors.

These are Carrying, Return, Impact, Self-aligning, Rubber lined, UHMWPE, polymer, TEFLON, etc.

Construction Features

Rollers are manufactured as per IS 8295 standards.Rollers can be supplied custom made.

- Roller Body: Shell is made of smooth surface ‘ERW’ steel tube as per IS : 9295 / IS 1239

- Rollers End: Bearing Housing made of CRCA press steel sheet with calibrated bearing seat, which are welded with the periphery of the steel tube, for maximum strength.

- Spindle: M.S. bright bars / EN-8 / EN-9 & precision ground at bearing and seal seating areas.

- Bearing: Precision single-row deep groove ball bearings with C3 clearance are provided. Distance between bearings and point of support at the shaft is very short and thus ensure higher load carrying capacity and longer service life.

- Sealing: The double multi labyrinth seal ensures optimum protection against the entry of dust and dirt in to the bearings. The sealing arrangement consist of Inner Seal , Dust Cover & Rain Cap

Polymer rollers

We are pleased to introduce non-metallic, polymer conveyor rollers suitable for corrosive and adverse applications. These rollers are made from High Density Polyethylene. The versatility of this material enables us to satisfy a varied range of uses where other plastic and metallic rollers have failed.

These rollers have following advantages:

- High wear & Chemical resistant

- Belt Protection: : When steel rollers fail they can produce sharp rotating edges, which can cut and rip conveyor belts at a very significant cost, causing unplanned down time and interruption to material supply. Also, cut conveyor belt traveling at high speed can pose a significant risk to employees working in the vicinity of the operating plant. Polymer rollers are a blessing here.

- Less Noise and Antistatic: The anti-static agent in this compound prevents sparking during operation in Volatile conditions. This is a sought after feature when considering usage such as underground-mining where gas build–up can occur as well as also dusty conditions in grain storage areas.

- Light Weight: 40 % to 50% Lighter than steel shell rollers.